45 polypropylene vs polyester labels

Do You Need Help Choosing A Label Material? - ABLT The test to determine which it is, is easy because Polyester sinks in water while Polypropylene floats. The hardest part of this test is that you must remove all the adhesive from the label first. This can take some time but by rubbing the back of the label with Goo Gone you can easily remove the adhesive. Polyamide Labels Vs. Polyimide Labels: What's The Difference? With a synthetic polymer structure, polyamide labels are made from synthetic resin. In essence, they're not a lot different to polyimide labels, as they can withstand similar temperatures. However, they're typically less expensive to manufacture. Here at Southern United, we offer a huge variety of materials and services.

Polyester vs. Polypropylene - What's the difference? | Ask Difference Polypropylene. Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polyester noun. a complex ester used for making fibers or resins or plastics or as a plasticizer. Polyester noun.

Polypropylene vs polyester labels

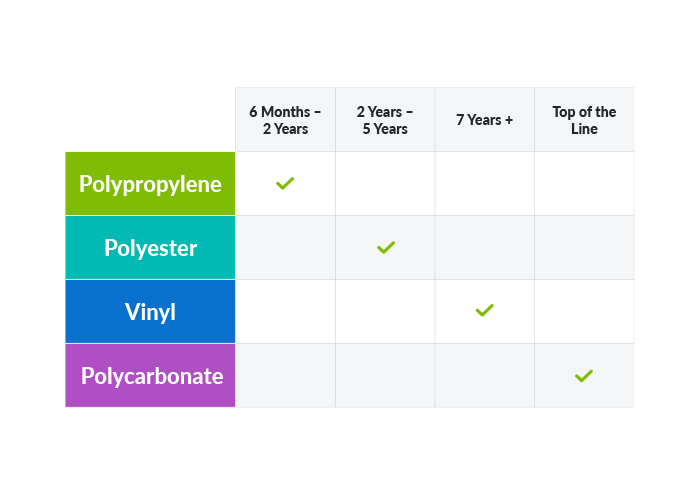

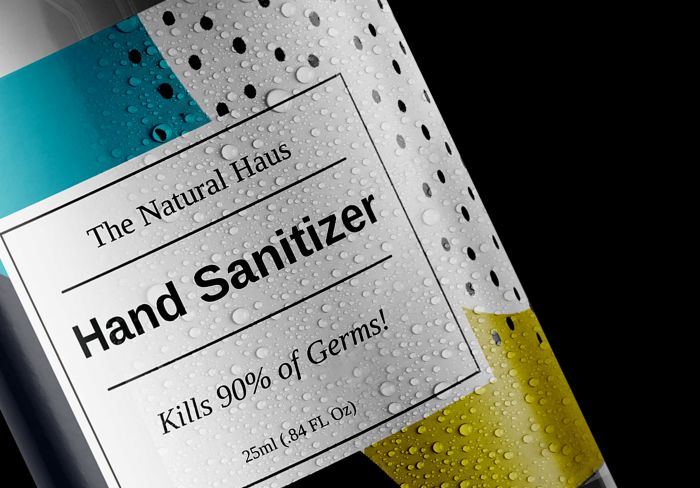

Label Materials & Descriptions | Know What Label Materials To Use - Whitlam Metalized Polyester. These polyester labels are available in either chrome, mirror-like finish, or a brushed finish that resembles stainless steel. This is an excellent material for outdoor use due to its dimensional stability and its ability to withstand harsh weather conditions. Useful for fleet markings, heating & air-conditioning units, or ... Ensuring your labels withstand your environment | Blog | CILS There is a massive difference between durability in the context of a label that will be stuck to a bottle of shampoo (polyethylene will be better than paper) versus the durability of a label that will be stuck to an industrial pump (polyester will be better than polypropylene). Polypropylene Labels - Everything You Need to Know Here are some disadvantages of using BOPP labels. Not Waterproof - BOPP labels are only water resistant, they are not waterproof. Medium Life Span - the typical lifespan of a BOPP label is 6 months to 2 years. If your application requires the label to last longer than 2 years, you might consider a polyester or vinyl label.

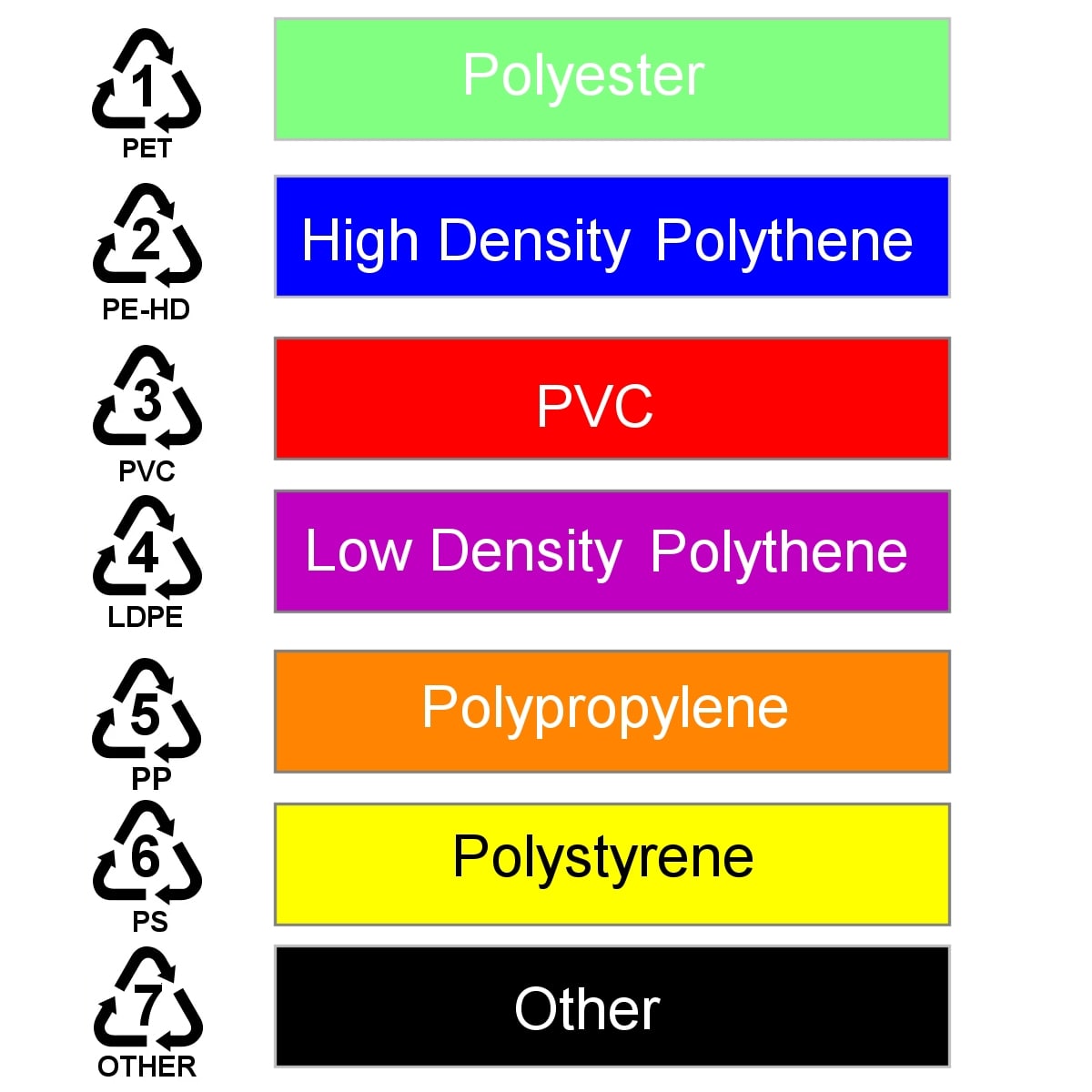

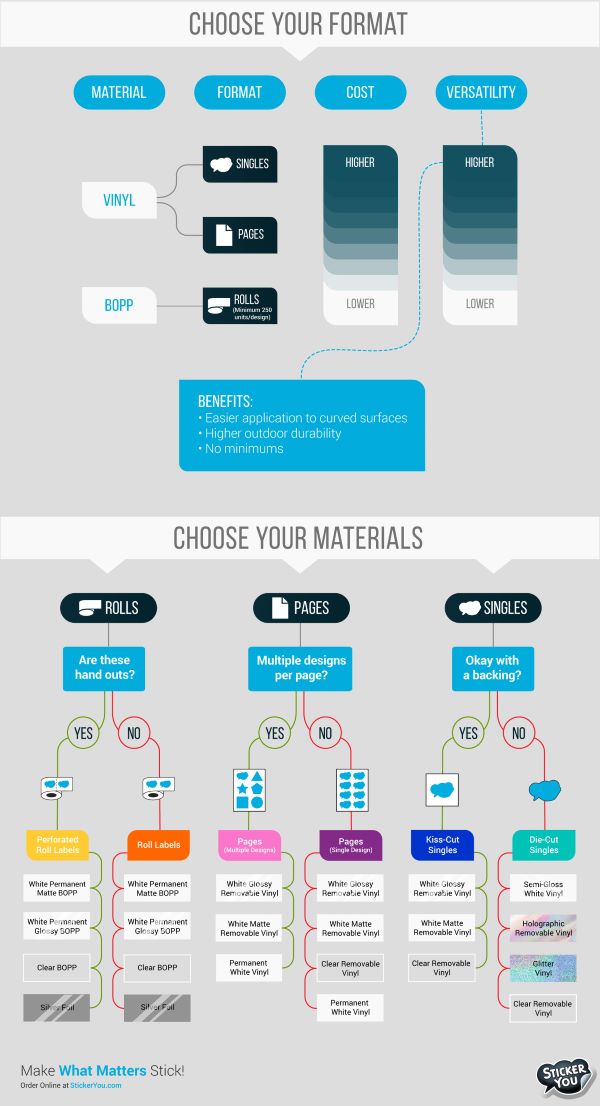

Polypropylene vs polyester labels. Paper or Plastic? Choosing the Right Label Face Stock for Your Barcodes It's good for product ID, and a typical polyester label is commonly used for labeling automobile parts. Polypropylene: These labels offer more durability than a paper face stock, but rate middle-of-the-road in terms of their UV, chemical, and temperature resistance. Poypropylene labels are well suited for inventory or labeling in cold ... Polypropylene vs Vinyl Stickers. Comparing Custom Label Printing ... In many cases, custom polyester labels are more cost-effective than vinyl because they are less durable. Polys are manufactured to be economically viable options for many label applications, however they are costlier than paper and there is a range of price depending on the specifications of the poly. cleanroomworld.com › cleanroom-apparelClean Room Suit | Clean Room Bunny Suit | Cleanroom Apparel Disposable Cleanroom Apparel vs Washable Cleanroom Apparel. The decision about whether to use disposable or washable cleanroom apparel often comes down to a variety of considerations, including convenience, the type of clothing, and how comfortable the clothing is. In addition, cost weighs into the choice. Poly Labels - Mylar, polyester, polypropylene, vinyl, polyolefin Poly labels really means a custom printed label made of a poly film material like Mylar (polyester, referred to as PET), polypropylene (commonly referred to as BoPP), or polyolefin (a combination of plastics made for a particular use). Vinyl labels and polystyrene labels can also be called "poly labels".

What is the difference between Polyester and Polypropylene labels? BarcodesInc. Polyester is the most rugged and is made for outdoor or extreme temp/chemical environments. Polypropylene is great for indoor use when you need something stronger than paper and not at a high cost like Polyester. Ask us your Barcode, POS, or RFID questions. 1-800-351-9962. Filed under: Question and Answer. Posted November 29, 2012. Polyester Vs. Polypropylene - What's The Difference? Fluid will pass through polypropylene without getting absorbed into the fibers. Polypropylene is better at repelling water. Although polyester can wick moisture too, it is no match for polypropylene. Polypropylene will wick moisture very fast, resulting in speedier drying. 3. Durability › labels › laboratoryChemical Resistant Cryogenic Polypropylene Labels for 3" Core ... Polypropylene (B-7425) material is ideal for general purpose barcode applications and withstands liquid nitrogen, autoclave and other harsh environments. Matte white polypropylene with acrylic adhesive is thermal transfer printable; Perfect for laboratory identification such as vials, centrifuge tubes and test tubes Polypropylene vs Polyethylene Label Materials: - Paramount Labels Metallic Polypropylene Labels: The PP label material has the same water and oil resistance as White PP and Clear PP. However the difference is in its light reflecting properties - the same as that of a metal. Colourwashing these materials are favoured by luxury brands for a magnificent display of Gold, Copper, Silver and Rose Gold effects.

› labelsBrady Labels: Printer Labels, Preprinted & Custom | BradyID.com These labels are designed to last in every application you have – from general facility ID to harsh washdown cycles or autoclave conditions. Our pre-printed and print-on- demand labels effectively communicate important safety messages that provide critical information or identify critical components and equipment in an emergency. What do the different types of plastic based labels mean- PVC,PP,PET ... PP = Polypropylene PET = Polyester BOPP = Biaxially Oriented Polypropylene PS = Pressure Sensitive Vinyl is mostly used for wall and floor graphics with an indoor application. Cheaper than polyester. Polyprop is a cheaper form of polyester, also mostly used for indoor application Polyester is the most expensive, basically weatherproof. Polyester vs. Polypropylene - Difference Wiki Polyesters have higher melting points as compared to polypropylene who melt at a much lower melting point and can be re-molded in required shapes. Polyester vs. Polypropylene Polyesters are less hydrophobic and absorb some water. On the other hand, polypropylene does not react with water and considered highly hydrophobic. Polyester vs vinyl labels | Electric Arc - ArcAdvisor This is considered a stronger material than vinyl since it is more tear resistant and can withstand exposure to oils, solvents, and a number of chemicals. Labels that are made using this material are ideal for products that are subjected to harsh indoor or outdoor conditions.

What is Facestock? An Overview of Label Materials From TLP Polypropylene's lack of resistance to the outdoor world generally causes a shorter life span compared to vinyl and polyester labels. However, this shorter life span is countered by polypropylene's excellent recyclability (when on a polypropylene container) as it is the most easily recycled material compared to vinyl and polyester.

Polyester vs Polypropylene Strapping: What's the Difference? Polypropylene strapping has a matte finish and is usually embossed. Tension retention - Polyester retains tension over a long period of time. Polypropylene has low retained tension, often losing about half of the applied tension with an hour of being applied. This loss can be accelerated by certain environmental factors as well.

A Guide to Polyester, Nylon, & Polypropylene Fabric Polypropylene is a lightweight type of plastic. It was originally used to mass-produce plastic items in factories, but nowadays it's most commonly a textile or fabric. The advantages of polypropylene include: Absorbs moisture Resistant to chemicals Thermal properties ideal for cold weather Resistant to tearing

Polypropylene (PP) vs Polyethylene (PET) Plastic - Brand My Cafe Blog While the filling temperature PET plastic can withstand is 160 degrees Fahrenheit, PP plastic can withstand fill temperatures up to 176 degrees Fahrenheit. It may not be a significant difference but needs to be considered for sensitive instances. PP plastic resists heat from outside better than PET.

Polypropylene vs. Polyethylene - Difference Wiki Polypropylene is a bad insulator while polyethylene is a good electrical insulator. PP has a higher melting point and a lesser cost than PE. PP weighs lighter than a PE. Polypropene is also more resistant to organic solvents and chemicals than polythene. PP can be made into fibers but PE cannot be made into fibers.

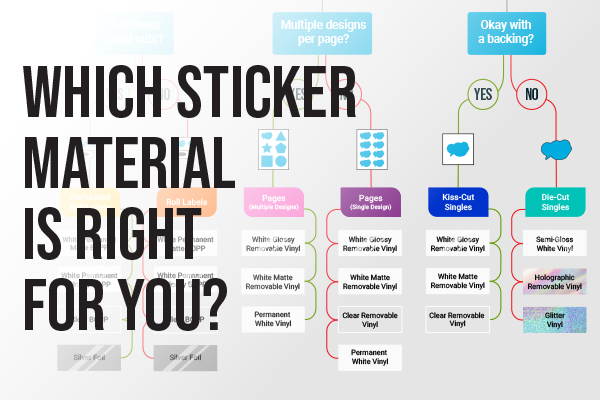

What is the difference between polyester and vinyl sticker? - Camaloon Material and durability The polyester stickers are better than the paper ones, and they are the perfect solution if you are looking for an alternative as a middle-ground between the vinyl stickers and other kinds. The material has a thickness of 58 μm and a glossy finish. For vinyl adhesives we use a white vinyl monomer.

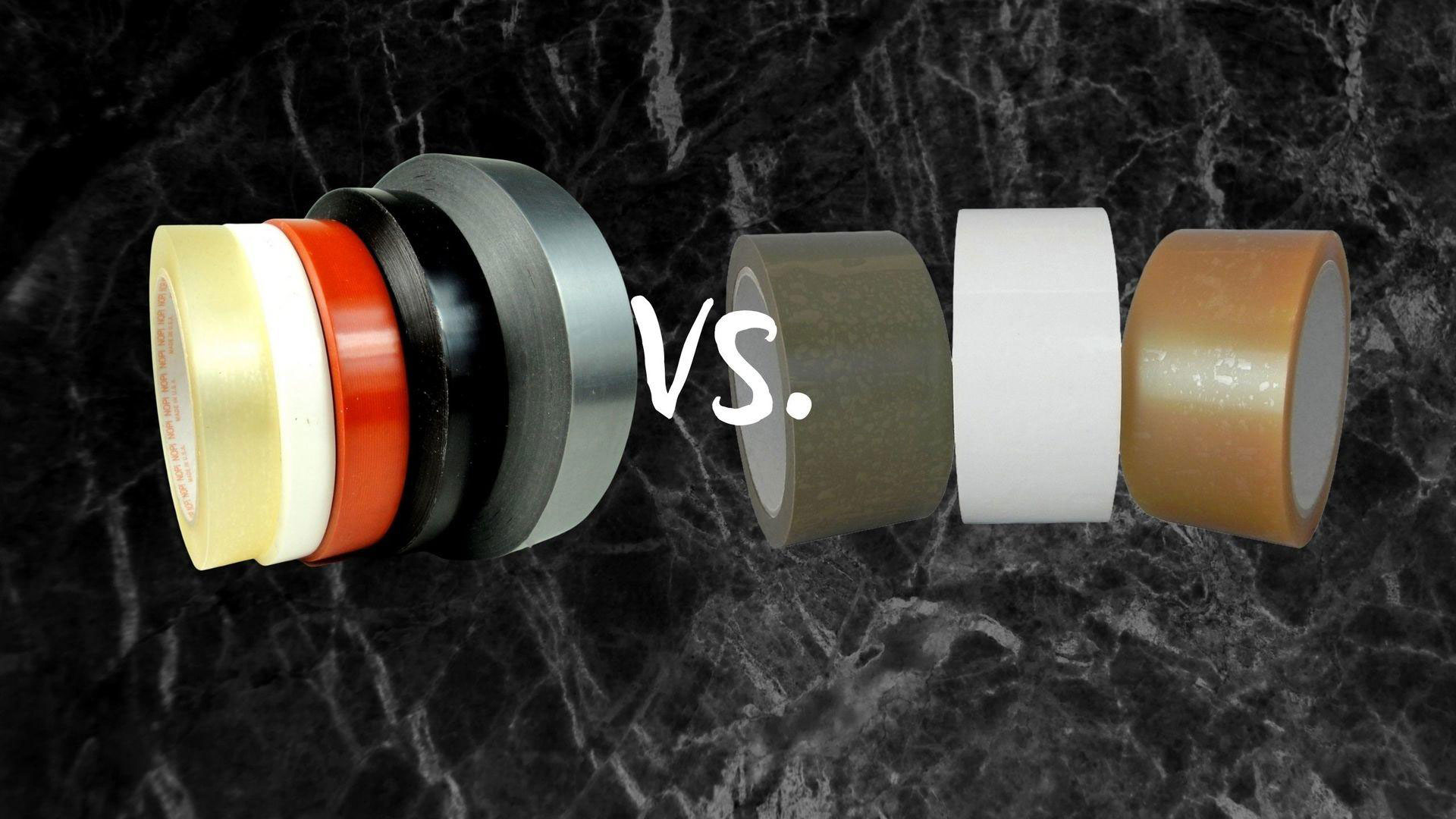

Polyethylene vs Polypropylene: Which Is Better? They are also highly conformable, which makes them usable in a wide range of sealing applications. Polypropylene tapes can have the same tensile strength and damage resistance as polyethylene tapes, the only difference being that they are more affordable than the latter. The downside, however, is that they can be noisy to use.

Polyester vs Polypropylene: What's the Difference? - Silver Bobbin The main difference between polyester and polypropylene is that polypropylene is more water-resistant than polyester, making it a quick-drying fabric that works well for athletic wear. Polyester lacks the quick-drying properties of polypropylene, but it is washable and wrinkle-resistant, qualities that make it easy to care for.

Is Polyester or Polypropylene the Right Choice for my Sleeves and Bags ... Polyester film is the material of choice for archiving many of the United States' most valuable historical documents according to the Library of Congress. Polypropylene is also archival safe, however it is gas permeable. Polyester sleeves and bags are more rigid than polypropylene counterparts. This gives polyester bags a brilliant, shiny surface.

Polypropylene Labels: What You Need to Know | LabelValue They are more durable than most labels and are tear-proof and waterproof. It is also resistant to fading and discoloration that is often characteristic of standard paper labels. Polypropylene labels are ideal for a wide range of retail packaging uses, such as hair care, cosmetics or pharmaceutical products.

pdihc.com › products › environment-of-careSani-Cloth® Plus Germicidal Disposable Cloth - PDI Healthcare The PDI Difference: Microfiber Cloths vs Ready To Use (RTU) Products. Are you wiping away your hard work? Microfiber cloths may do more harm than good. While microfiber cloths… Sani-Cloth® Plus Caution Sign. This precautionary sign for Sani-Cloth Plus wipes has easy-to-identify contact time, not a skin or baby wipe, and…

Polyamide vs Polyester: 12 Differences And What Is Better That fabric is seen as softer, more comfortable, and is oil resistant while polyester doesn't resist oil and while close to polyamides for the other two, it does not beat polyamide out in those categories. For winter, polyester would be the better fabric while polyamide material would be better for warmer days.

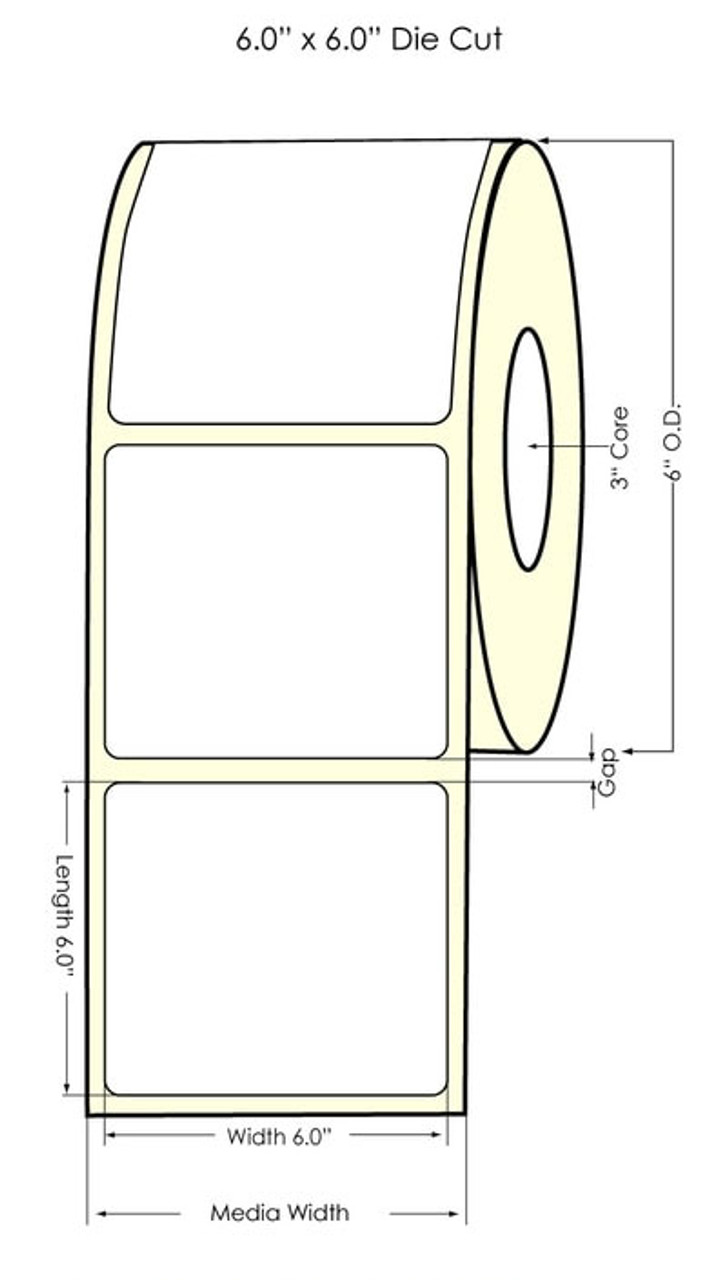

Zebra 3 x 1 in Thermal Transfer Polypropylene Labels PolyPro 3000T Permanent Adhesive Shipping Labels 1 in Core 8 rolls 10031648SP

- Largest Manufacturers & Products Search ... Import & Export on our award-winning International Trade Site, Find quality Products, Trade Leads, Manufacturers, Suppliers, Buyers and Wholesalers.

www2.chemistry.msu.edu › faculty › reuschPolymers - Michigan State University The polyester Dacron and the polyamide Nylon 66, shown here, are two examples of synthetic condensation polymers, also known as step-growth polymers. In contrast to chain-growth polymers, most of which grow by carbon-carbon bond formation, step-growth polymers generally grow by carbon-heteroatom bond formation (C-O & C-N in Dacron & Nylon ...

7 Important Types of Label and Sticker Materials - PLCTX BLOG Polypropylene labels are affordable than polyester labels, and they offer better clarity. These labels are distinguished on the basis of their coating, adhesive, and colors. The following are some popular types of these labels: i) Chrome (Silver) BOPP Labels:: This label material is oil and water-resistant, and has a mirror-like finish.

› heat-transfersAll Products For Custom Heat Transfers - 613 Originals For Cotton, Nylon, Polyester and Stretch. Our best value! Our screen printed heat transfers go on several fabric types including 100% poly and cotton blends. Single image 9" x 12.75" only 15¢ each + set up. Formula Variations. 15¢ Transfers - For Cotton/Polyester ; 25¢ Transfers - Varsity Leg / Sleeve Print; 15¢ Transfers - For Nylon

Label Materials - What Is My Label Made Of? - The Label Experts Polyethylene (PE) Floats. Easy. Lightweight, flexible, good abrasion resistance, preferred for packaging. Polypropylene (PP) Floats. Somewhat Difficult. Chemical & scratch resistant, strong, good wide service temperature. NOTE: The concept behind the water float test involves "specific gravity.".

Polypropylene Labels - Everything You Need to Know Here are some disadvantages of using BOPP labels. Not Waterproof - BOPP labels are only water resistant, they are not waterproof. Medium Life Span - the typical lifespan of a BOPP label is 6 months to 2 years. If your application requires the label to last longer than 2 years, you might consider a polyester or vinyl label.

Ensuring your labels withstand your environment | Blog | CILS There is a massive difference between durability in the context of a label that will be stuck to a bottle of shampoo (polyethylene will be better than paper) versus the durability of a label that will be stuck to an industrial pump (polyester will be better than polypropylene).

Label Materials & Descriptions | Know What Label Materials To Use - Whitlam Metalized Polyester. These polyester labels are available in either chrome, mirror-like finish, or a brushed finish that resembles stainless steel. This is an excellent material for outdoor use due to its dimensional stability and its ability to withstand harsh weather conditions. Useful for fleet markings, heating & air-conditioning units, or ...

Post a Comment for "45 polypropylene vs polyester labels"